42

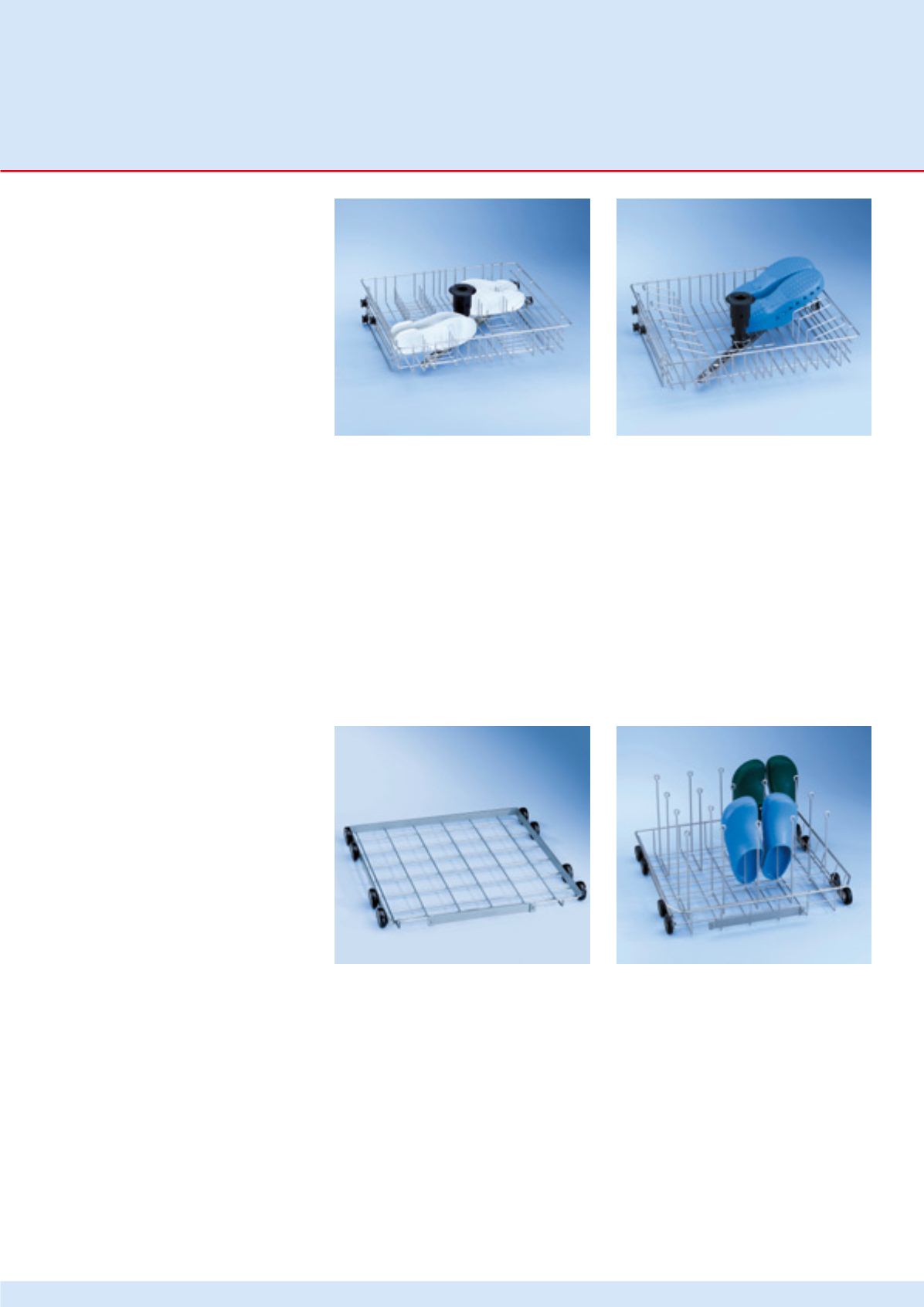

U 168/1 lower basket

• For up to 20 theatre shoes, max. Size 45

• 20 holders, 295 mm

•With holder for ML/2 magnetic strip for

automatic mobile unit recognition

• H 315, W 535, D 515 mm

U 874/1 lower basket/open front

• For E 484 adapter

• Open front

• For various inserts

• Vertical clearances in combination with

upper basket:

O 176 approx. 110 mm

O 177/1 approx. 220 mm 20-40 mm

O 183 approx. 185 mm +/–20 mm

O 188/1 approx. 270 mm +/–20 mm

O 190/1 approx. 220 mm +/– 20 mm

O 191 approx. 295 mm

•With holder for ML/2 magnetic strip for

automatic mobile unit recognition

• H 50, W 534, D 515 mm

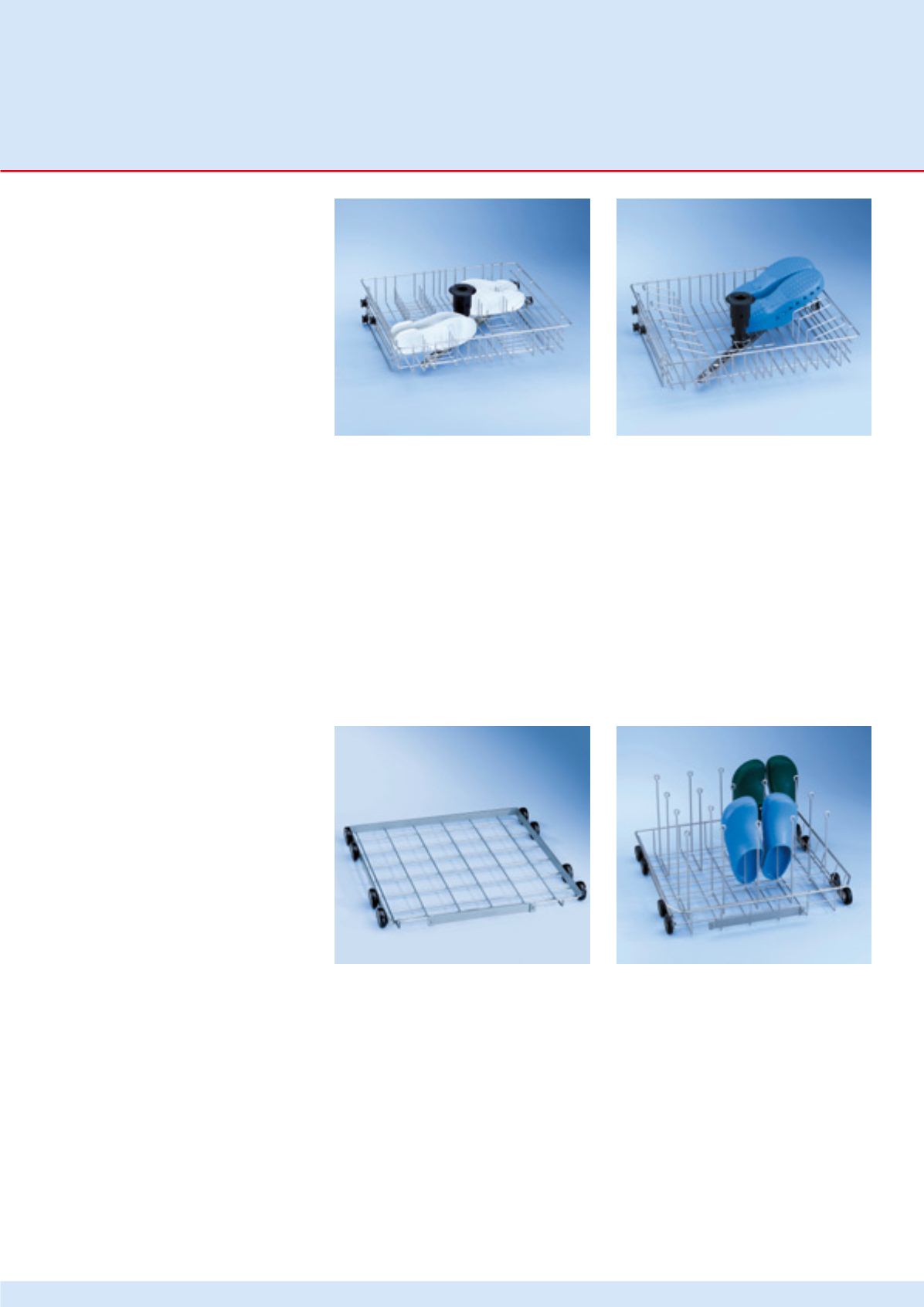

O 167 upper basket

• For up to 28 theatre shoe insoles

• Built-in spray arm

• H 195, W 531, D 475 mm

O 173 upper basket

• For up to 8 theatre shoes, max. Size 41

• Built-in spray arm

• H 195, W 531, D 475 mm

Inserts for theatre shoes

Theatre shoes should be thoroughly

washed and disinfected after operations.

Most common are theatre shoes made

from polyurethane (PU). In the past, the

automatic reprocessing of these heat-

sensitive items relied on chemo-thermal

processes and a temperature of 60°C

with a 5-minute holding time. However,

the chemical disinfectants involved pose

handling problems and are costly.

After intensive trials, Miele has now

developed a purely thermal reprocessing

method for theatre shoes which has been

validated in practice.

This reprocessing programme is available

on models PG 8535 and PG 8536.

Thorough washing at temperatures below

55°C is followed by thermal disinfection in

the last water intake cycle at a temperature

of 75°C held for 2 minutes. At 22 minutes

(excluding drying), this new process is

considerably shorter than chemo-thermal

processes (approx. 37 minutes) and

dispensing with chemical disinfectants

offers both environmental and economical

benefits.